Introduction to Hydraulic Flow Meters

Welcome to our comprehensive guide on hydraulic flow meters! If you’re in hydraulics, you know just how crucial it is to have accurate fluid flow measurements. That’s where hydraulic flow meters come into play – these nifty devices provide invaluable data that can help optimize performance, ensure efficiency, and prevent costly breakdowns.

Whether you’re a seasoned professional or new to the field, this guide will take you through everything you need about hydraulic flow meters. We’ll cover the different types available, how they work their magic and the wide range of applications where they prove indispensable.

Types of Hydraulic Flow Meters

Hydraulic flow meters are essential for measuring hydraulic fluids’ flow rate in various systems. Several types of hydraulic flow meters are available, each with unique features and benefits.

1. Differential Pressure Flow Meters: This type of flow meter measures the pressure difference between two points in a pipe to determine the fluid flow rate. It is cost-effective and widely used in many applications.

2. Turbine Flow Meters: These meters utilize a turbine rotor that spins as the fluid flows through it, converting the rotational motion into an electronic signal. They offer high accuracy and can handle a wide range of flow rates.

3. Ultrasonic Flow Meters: Using ultrasonic waves to measure velocity, these meters are non-intrusive and ideal for large pipes or applications where minimal pressure loss is crucial.

4. Magnetic Flow Meters: Also known as magmeters, these devices use electromagnetic sensors to measure the voltage generated by the moving conductive fluid. They are highly accurate and suitable for conducting water or wastewater.

5. Positive Displacement Flow Meters: These meters trap discrete volumes of fluid within their chambers and then count them to calculate the total volume or flow rate accurately.

6. Vortex Shedding Flow Meters: These meters monitor vortex shedding from an obstruction placed in the path of flowing liquid, indirectly measuring flow rate based on frequency changes.

Each type has its advantages depending on factors like budget, application requirements, accuracy needed, and compatibility with specific hydraulic fluids being measured.

How Do Hydraulic Flow Meters Work?

Hydraulic move meters are essential for measuring hydraulic fluids’ move rates in various applications. They operate based on the principle of fluid dynamics, using different mechanisms to accurately measure the volume or velocity of fluid passing through a specific point.

One common type of hydraulic move meter is the variable area move meter, also known as a rotameter. It is made up of a float and a tapered tube. Fluid moving through the tube creates an upward force on the float, causing it to rise or fall depending on the movement rate. The position of the float indicates the rate at which fluid is flowing.

Another type is the turbine move meter, which uses rotating blades inserted into the flowing liquid stream. As fluid passes over these blades, they spin at a speed directly proportional to their velocity. A sensor detects this rotation and converts it into an electrical signal that can be displayed as a move rate.

Electromagnetic move meters work by applying Faraday’s law of electromagnetic induction. When conductive fluids pass through magnetic fields generated by coils in the meter, an electromotive force is induced across electrodes located within their path. This voltage is directly proportional to both fluid velocity and conductor length.

Ultrasonic Doppler effect-based meters emit ultrasonic waves into moving fluids and detect changes in frequency caused by particles suspended within them (such as air bubbles). By analyzing these frequency shifts, they can determine move rates accurately.

Benefits of Using Hydraulic Flow Meters

Accurate measurement and control of fluid flow are crucial in many industries, and that’s where hydrostatics flow meters come into play. These devices offer a range of benefits that make them indispensable tools for businesses.

One significant advantage of using hydrostatics move meters is their ability to provide accurate and reliable measurements. This ensures you have precise data on how fluids move through your system. With this information, you can monitor performance, detect abnormalities, and take corrective actions promptly.

Additionally, hydrostatics flow measures help optimize efficiency by allowing you to identify areas with excessive or insufficient fluid flow. By monitoring the move rates, you can adjust settings or make necessary repairs to ensure optimal operation and reduce energy consumption.

Another benefit is improved process control. Hydrostatics flow measures enable operators to maintain consistent flow rates within desired para measures. This level of control helps prevent equipment damage caused by overloading or inadequate lubrication.

Furthermore, with the ability to accurately measure liquid levels or volumetric moves in various applications such as oil refineries, chemical plants, and wastewater treatment facilities, hydrostatics move measures ensure compliance with regulatory requirements.

Hydraulic movement measures also contribute to cost savings by reducing waste and minimizing downtime due to system failures. By detecting leaks or blockages early on, these devices allow for timely maintenance interventions before more significant issues arise.

Common Applications of Hydraulic Flow Meters

Hydraulic flow meters are widely used in various industries due to their ability to accurately measure the flow rate of hydrostatic fluids. Here are some typical applications where these measures play a crucial role:

1. Industrial Machinery: Hydrostatics move meters are essential in industrial machinery such as pumps, motors, and valves. They help monitor and control the move rate of hydrostatics fluids, ensuring optimal performance and preventing damage or inefficiencies.

2. Oil and Gas Industry: In this industry, hydrostatics move meters are used for measuring the move rates of oil, gas, and other fluid media during extraction, processing, transportation, and distribution processes. Accurate measurement is vital for efficient operations and accurate billing.

3. Aerospace Engineering: Hydrostatic systems are critical in aircraft operation. Move meters ensure precise fuel consumption measurement during flight while monitoring the hydrostatics fluid levels for the safe functioning of landing gears and other components.

4. Automotive Industry: In automobiles with hydrostatics systems like power steering or braking systems, move meters help regulate fluid pressure by monitoring the volume flowing through different components.

5. Water Management Systems: Hydrostatic flow meters enable effective management of water resources by providing accurate measurements in irrigation systems, water treatment plants, wastewater management facilities, etc.

6. Manufacturing Processes: Various manufacturing processes involve hydraulics for accurately controlling movement or applying force to machinery or equipment parts. Flow meters ensure consistent performance by regulating fluid flows precisely.

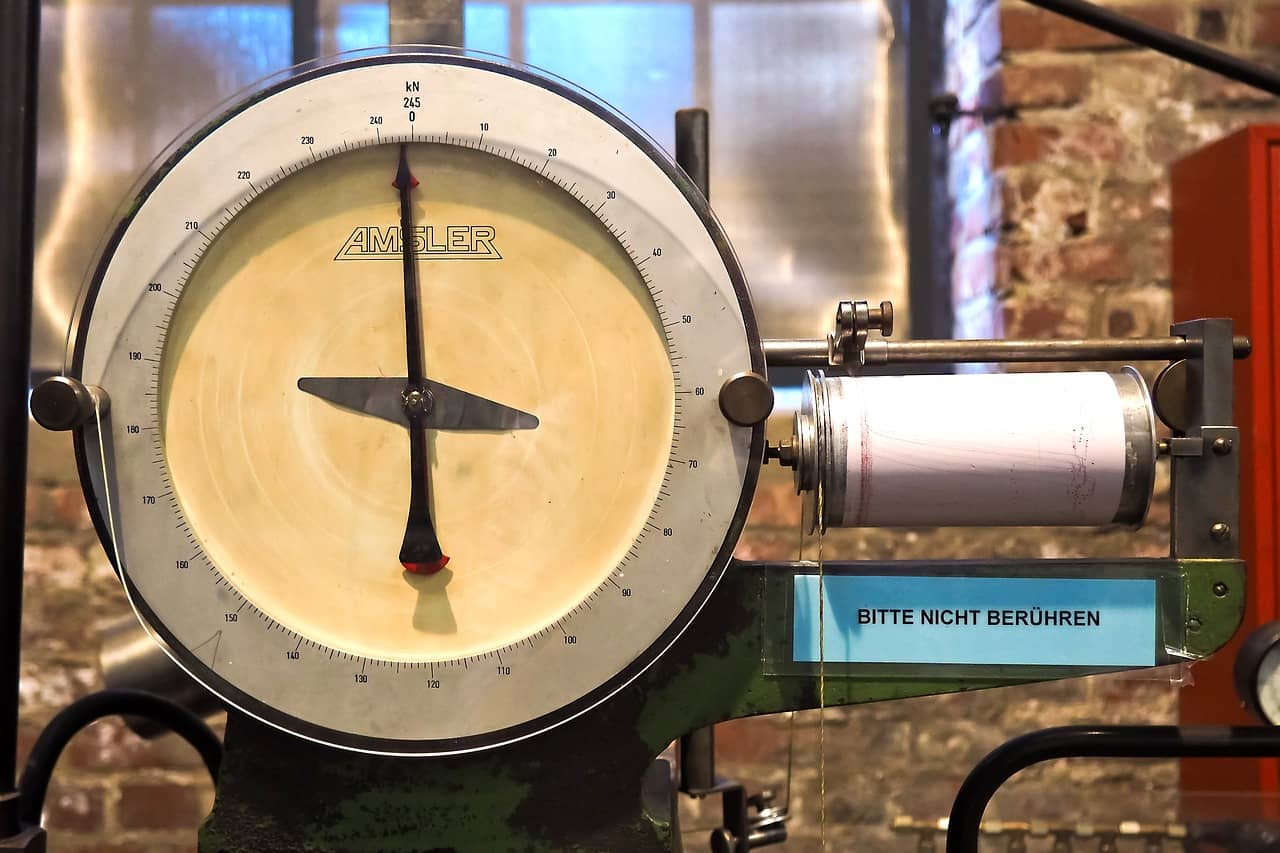

Laboratories & Research Facilities – Hydrostatics flow Meters find applications in laboratories & research facilities that deal with experiments involving pressurized liquids, such as chemical reactions studies or material testing procedures requiring controlled flows.

Choosing the Right Hydraulic Flow Meter for Your Needs

Choosing the proper hydraulic flow meter is crucial to ensure accurate measurement and optimal performance in your hydrostatics system. With various move measures available, it can be overwhelming to determine which one suits your needs best.

Think about the kind of fluid you intend to measure. Different fluids have different viscosity levels, so selecting a moving measure that can handle the specific viscosity range is essential for accurate readings. Additionally, consider the pressure and temperature limits of the move measure to ensure compatibility with your system’s operating conditions.

Next, assess your required move rate range. Flow measures come with different maximum capacities, so choose one that can accommodate your system’s highest possible move rate.

Another essential factor to consider is the accuracy requirements of your application. Some applications require precise measurements, while others have more lenient tolerances. Selecting a moving measure with an appropriate accuracy level ensures reliable data collection.

Consider whether you need a local display or if remote monitoring options are necessary for your application. Local displays provide real-time information on-site, while remote monitoring allows for data logging and analysis from a central location.

Take into account factors such as installation requirements and maintenance considerations. Some move measures require specific mounting orientations or additional accessories for proper functioning. Maintenance requirements vary between models; choose one that aligns with your capabilities and resources.

By considering these factors carefully, you can select a hydrostatics move measure that meets all your specifications and ensures efficient operation of your hydrostatics system without compromising accuracy or reliability.

Maintenance and Troubleshooting Tips for Hydraulic Flow Meters

Proper maintenance of hydrostatics move measures is crucial to ensure accurate readings and prolong their lifespan. The following are some vital pointers to remember:

Regular cleaning: It’s essential to regularly clean the move measure to prevent debris or contaminants from affecting its performance. Use a mild detergent and water solution, followed by thorough rinsing.

Inspect for leaks: Check all connections and fittings for any signs of leakage. Even minor leaks can lead to inaccurate readings or damage the move measure over time.

Calibration checks: Periodically verify the calibration of your hydrostatics move measure using a known standard. This will help identify any inconsistencies in measurements and allow you to make necessary adjustments if required.

Monitor fluid conditions: Keep an eye on the condition of the fluid passing through the move measure. Contaminated or degraded fluids can impact accuracy, so addressing any issues promptly is essential.

Troubleshooting common problems:

– If you notice sudden fluctuations in readings, check for air bubbles or blockages in the system.

– Inspect the impeller assembly for obstructions or damage in case of zero-flow readings.

– Excessive noise during operation could indicate worn-out bearings that need replacement.

Remember, proper maintenance practices go hand-in-hand with troubleshooting skills to ensure optimal performance from your hydraulic flow meter. You can rely on accurate measurements and extend its lifespan by promptly addressing issues.

Conclusion

In wrapping up this comprehensive guide to hydraulic move meters, it is evident that these devices play a crucial role in various industries where fluid move measurement is essential. We have explored the different hydraulic move-meter types available, including paddle wheel, turbine, and ultrasonic options.

Understanding how hydraulic move meters work is vital for accurately measuring and monitoring fluid moves. From measuring water usage in residential settings to watching oil moves in industrial applications, these devices offer valuable insights into the efficiency and performance of hydraulic systems.

The benefits of using hydraulic move meters are numerous. They provide real-time data on fluid moves, allowing for better control and optimization of processes. These devices also help detect potential issues or leaks early on, preventing costly downtime and repairs.

Typical applications for hydraulic flow meters range from HVAC systems and irrigation systems to chemical processing plants and oil refineries. Because of their adaptability, they are essential tools for various industries.

When selecting a hydraulic move meter for your specific needs, consider factors such as the type of fluid being measured, desired accuracy level, installation requirements, and budget constraints. Consulting with an expert can ensure you choose the suitable device for optimal performance.

Regular maintenance is essential to keep your hydraulic move meter functioning correctly. Follow manufacturer guidelines for cleaning and calibration procedures to maintain accuracy over time.

To summarize this guide without actually concluding it (because who likes conclusions anyway?), understanding the basics of hydraulic move meters empowers users with knowledge that can enhance productivity while ensuring efficient operations within their respective industries.

FAQS

1. What is a hydraulic flow meter?

A hydraulic flow meter is a device used to measure fluid flow rate in a hydraulic system. It provides accurate and reliable data on fluid velocity, volume, and pressure within the system.

2. What are the types of hydraulic flow meters?

Several hydraulic flow meters are available, including paddle wheel meters, turbine meters, ultrasonic clamp-on meters, and electromagnetic meters. Each type has its advantages and applications.

3. How do hydraulic flow meters work?

Hydraulic flow meters operate based on different principles, such as measuring rotational speed or using sound waves to determine fluid velocity. They typically consist of sensors that detect changes in fluid movement and convert them into usable data.

4. What are the benefits of using hydraulic flow meters?

Using hydraulic flow meters offers numerous benefits, such as improved efficiency and productivity by optimizing fluid usage, enhanced system performance through accurate measurements, early detection of potential issues or leaks, and better control over operations for increased safety.

5. Where can I use hydraulic flow meters?

Hydraulic flow meters have diverse applications across various industries, such as oil and gas, manufacturing, agriculture, wastewater treatment plants, automotive industry testing facilities, and more. They are commonly used in systems requiring precise measurement and control of fluids.

6. How do I choose the proper hydraulic floor meter?

When selecting a suitable hydraulic floor meter for your requirements, you should consider factors like maximum operating pressure, capacity range, repeatability accuracy level, suitability with measured fluids, budget constraints, and any additional features required to meet your application demands.